| Home | Gallery | Emergency Help | Contact Us |

|

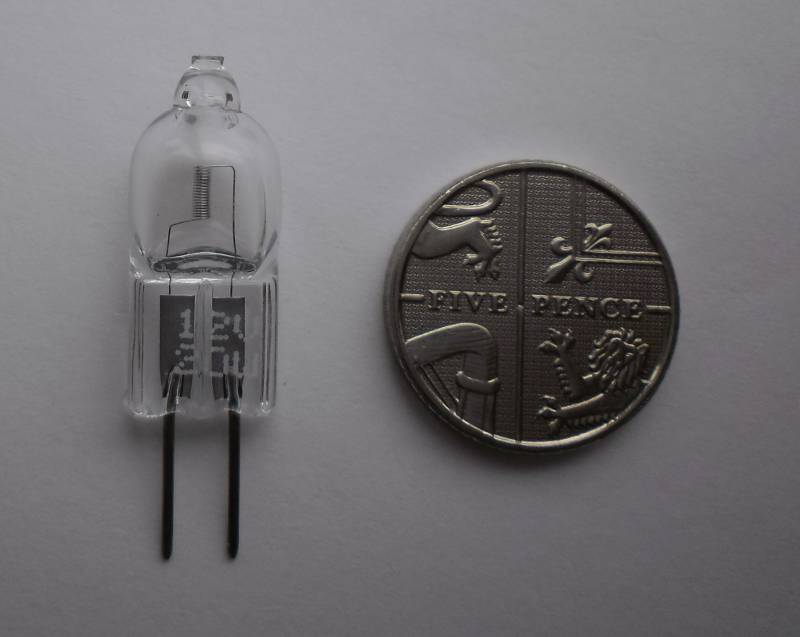

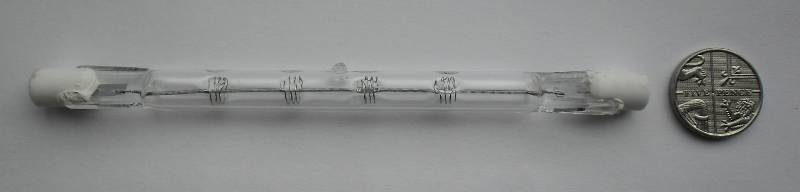

Halogen or (Quartz) Tungsten / Halogen lighting evolved from

incandescent filament lighting

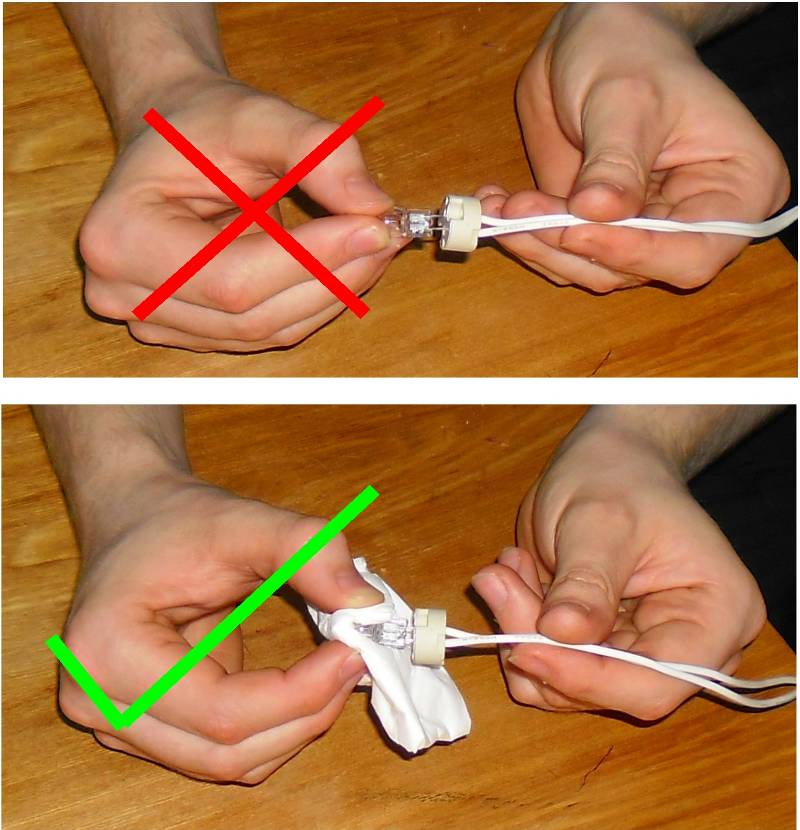

. Essentially, the Tungsten filament used in an incandescent filament light is mounted in a light bulb similar to an incandescent filament light, but with a small quantity of a "halogen" element added (compounds of either Iodine or Bromine) to the bulb once the air has been pumped out. The halogen gas and the tungsten filament produces a halogen cycle chemical reaction inside the glass bulb and redeposits evaporated tungsten back on the filament, increasing the filament's life. A halogen lamp can (and does) operated at a higher temperature than a standard incandescent filament lamp and because it operates at a higher temperature, the glass in the bulb needs to be quartz glass. When handling Halogen lamps, you must be careful not to contaminate the glass with the natural oils on your fingers as this greatly reduces the life of the lamp. Always wear gloves, or use a paper tissue or cotton wool when replacing Halogen lamps to avoid touching the glass. |